MGB’s innovative, scalable technologies deliver immediate benefits, reducing costs and improving ESG.

A recent study in 2022 revealed that MGB technologies generated equipment and fuel savings of over $500,000 for three pads, while also reducing Carbon Dioxide emissions by 1,500 metric tons.

The Benefits

Houston Area Based

MGB is headquartered in Katy, TX, with manufacturing, sales & service locations in Brookshire and West Texas. Our facility locations allow MGB to deliver advanced well services and pressure pumping equipment to enhance our customer’s operations.

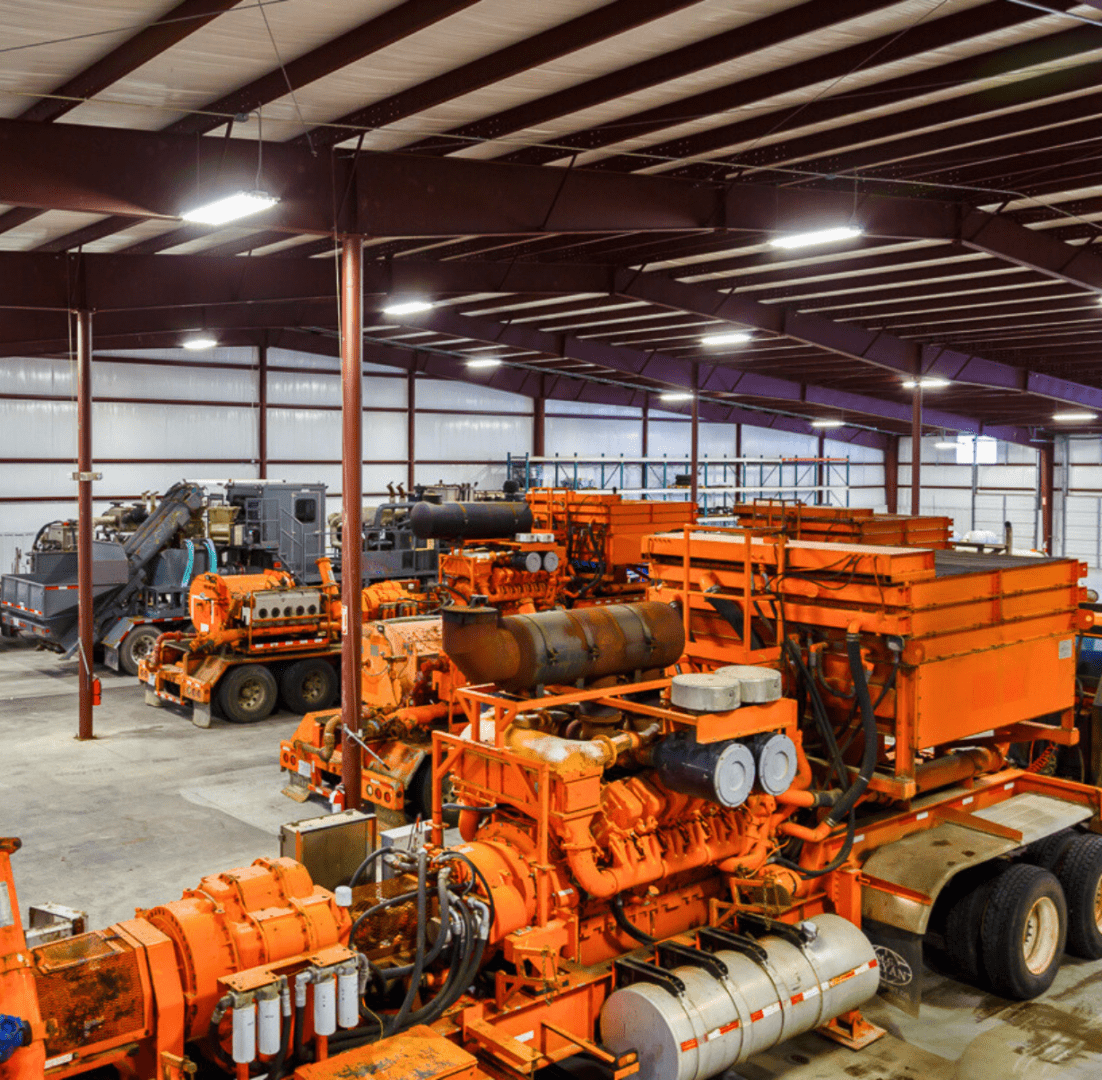

Manufacturing Infrastructure

Our engineering and manufacturing facility sits on ten acres with 32,510 ft² of manufacturing space under one roof, complete with full testing capabilities. MGB provides the skill and infrastructure to manufacture, test, service, repair, and rebuild virtually any well-servicing/pressure pumping equipment.

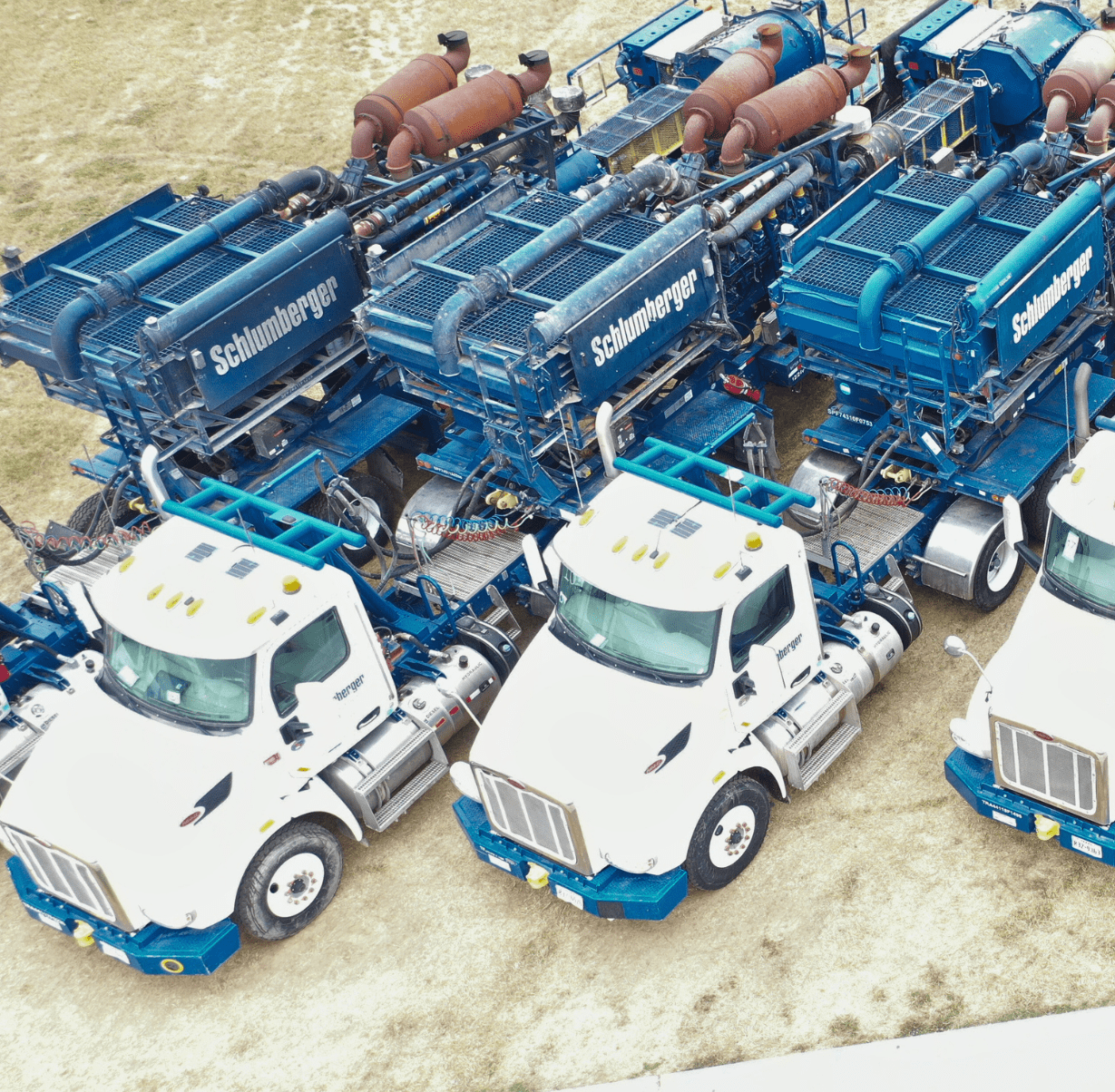

Equipment Expertise

With our team of industry experts, MGB is able to provide the skill and infrastructure to manufacture, test, service, repair, and rebuild virtually any hydraulic stimulation equipment, keeping our customer’s operations running.

Houston Area Based

MGB is headquartered in Katy, TX, with manufacturing, sales & service locations in Brookshire and West Texas. Our facility locations allow MGB to deliver advanced well services and pressure pumping equipment to enhance our customer’s operations.

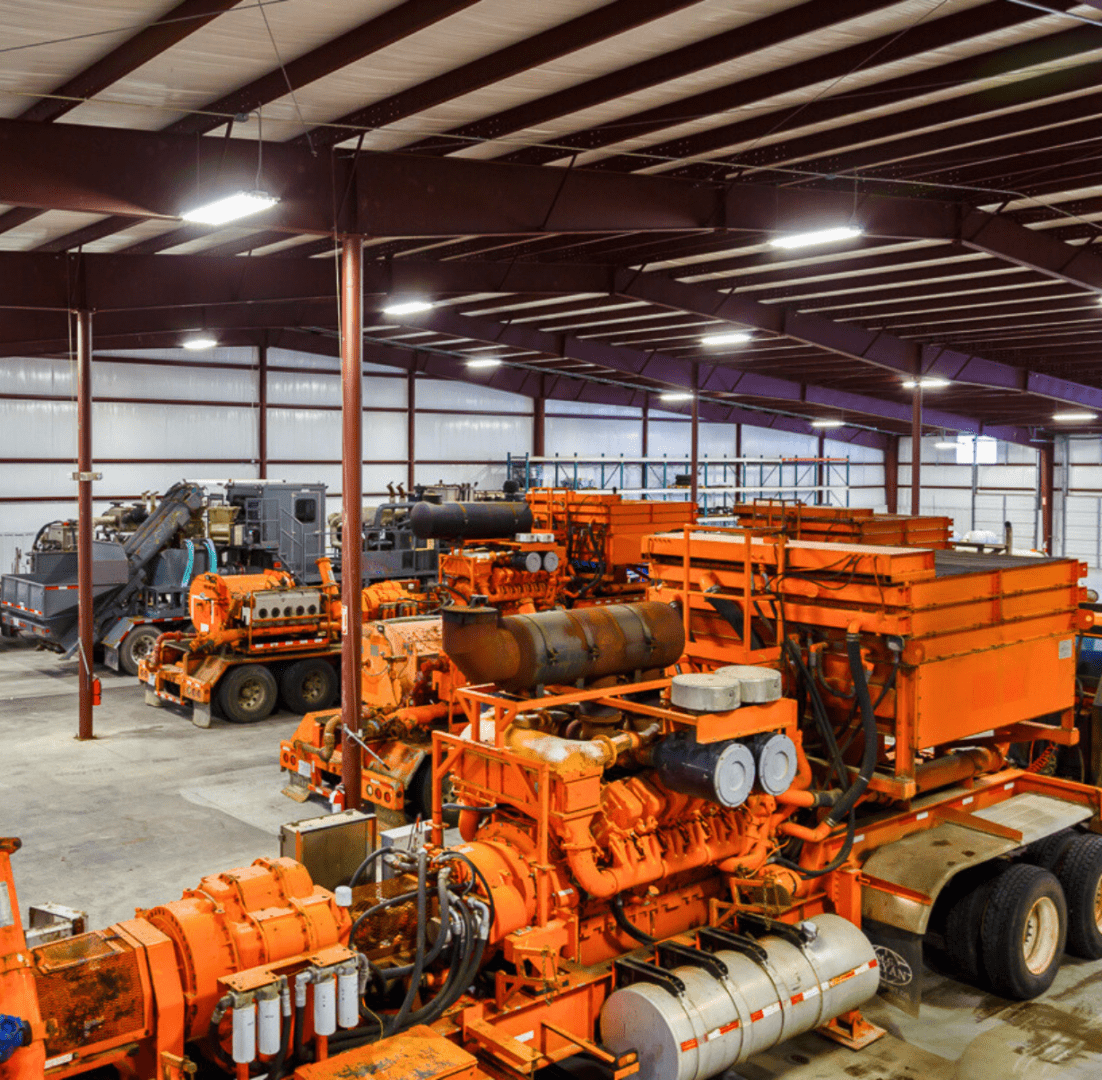

Manufacturing Infrastructure

Our engineering and manufacturing facility sits on ten acres with 32,510 ft² of manufacturing space under one roof, complete with full testing capabilities. MGB provides the skill and infrastructure to manufacture, test, service, repair, and rebuild virtually any well-servicing/pressure pumping equipment.

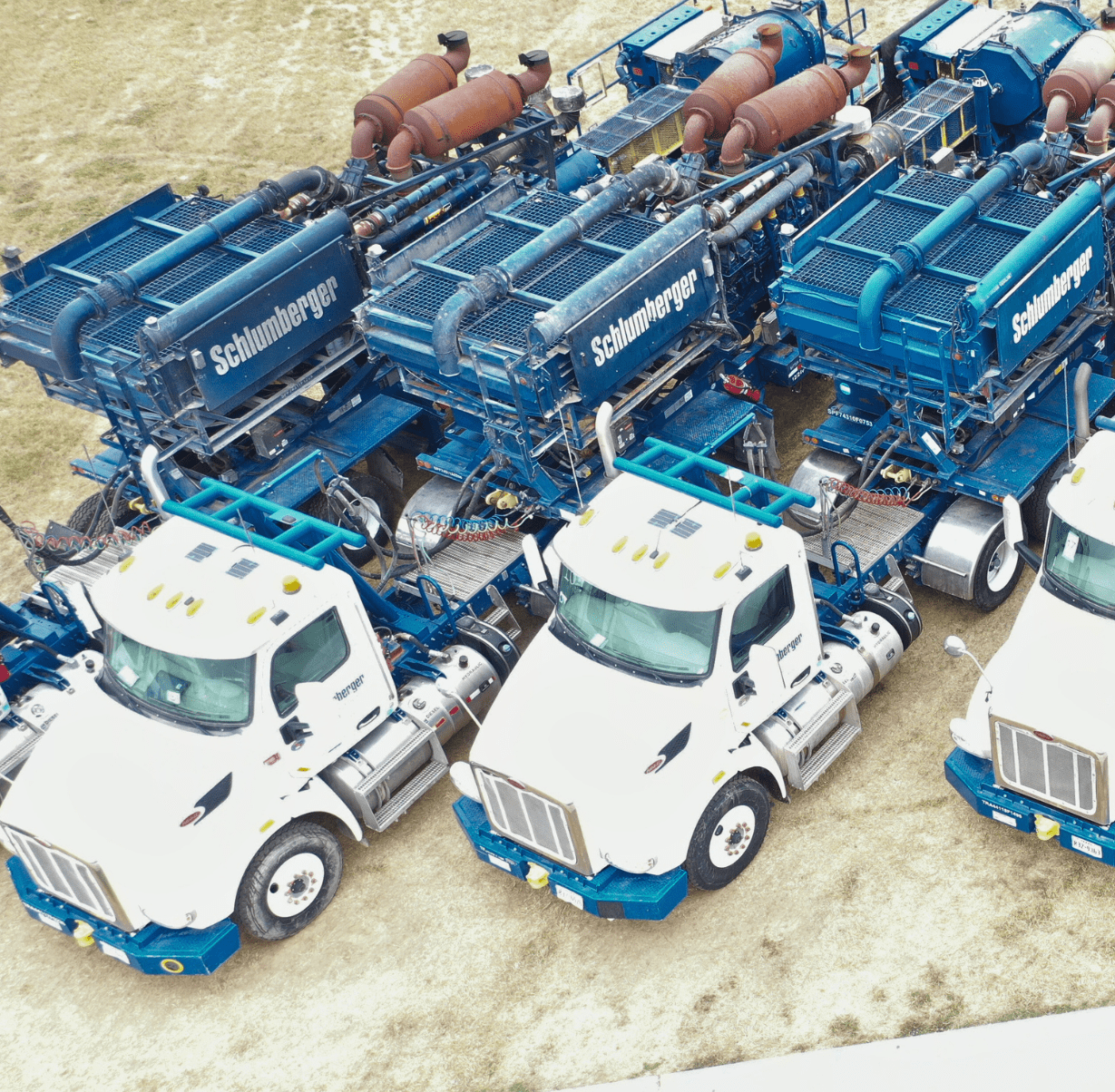

Equipment Expertise

With our team of industry experts, MGB is able to provide the skill and infrastructure to manufacture, test, service, repair, and rebuild virtually any hydraulic stimulation equipment, keeping our customer’s operations running.

Our unique Designed For (DF) Process

We create next-generation equipment using the best components and the lowest total cost of ownership. Our design philosophy is a significant step-change in how equipment is operated and maintained, and we consider all assets as a system, not just individually. Our experience and expertise in-house, along with our unique Designed For (DF) Process and Fault Mode Effect & Cause Analysis (FMECA), enable us to produce a world-class product that offers the lowest total cost of operation for the end-user, from CAPEX to OPEX.

Operations. Designed specifically with operations teams in mind, and how end-users would operate the asset, from intuitive designs, control systems, human/machine interface, reliability, and operator training requirements..

HSE. Focused approach on reducing and eliminating as much of the potential HSE risks associated with manufacturing, operating and maintaining the equipment, as well as environmental compliance and stewardship..

Maintenance. We design systems and equipment that requires fewer maintenance tasks, thus reducing the amount of manpower required to maintain the asset, as well as extending the periodic maintenance interval times.

Reliability. Ensuring that all components selected to make up the asset, truly are the best in class and that they seamlessly integrate. Achieving best-in-class reliability will reduce the number of back up equipment required and significantly reduce their Non-Productive Time (NPT).

.

Supply Chain. Careful selection of all components from a supply chain perspective ensures all parts are proven, readily available, well supported by various OEMs, and create value in lowering the total cost of ownership.

Manufacturing. We strive to manage the entire manufacturing process most cost-effectively, thus reducing the total cost of manufacturing, ensuring each unit is manufactured to the same exacting standards and specifications.