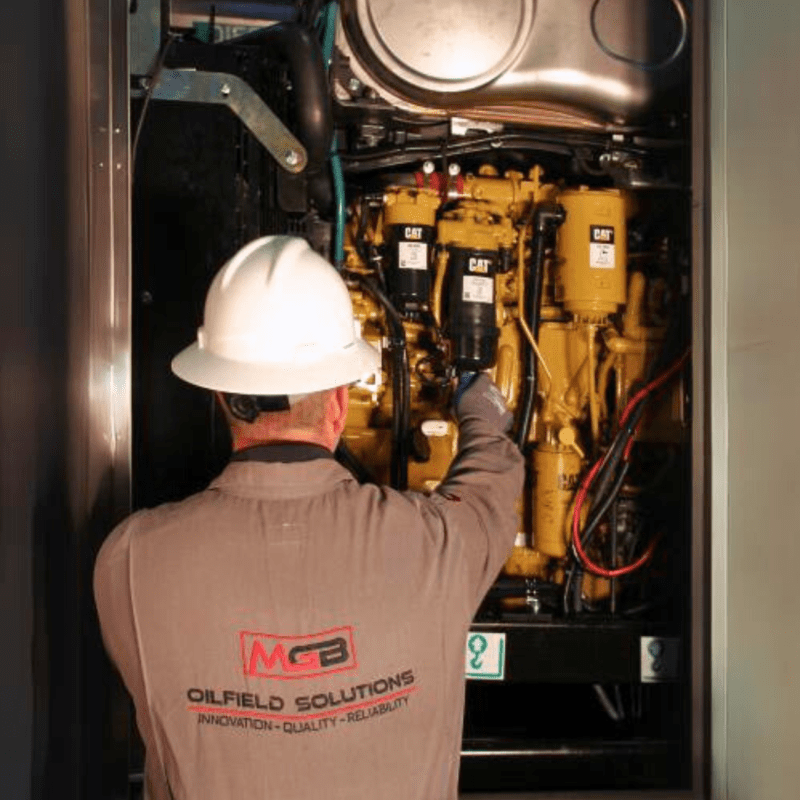

MGB’s mission is to partner with operators and service companies to introduce innovative technology solutions, drive efficiency, and improve wellsite safety.

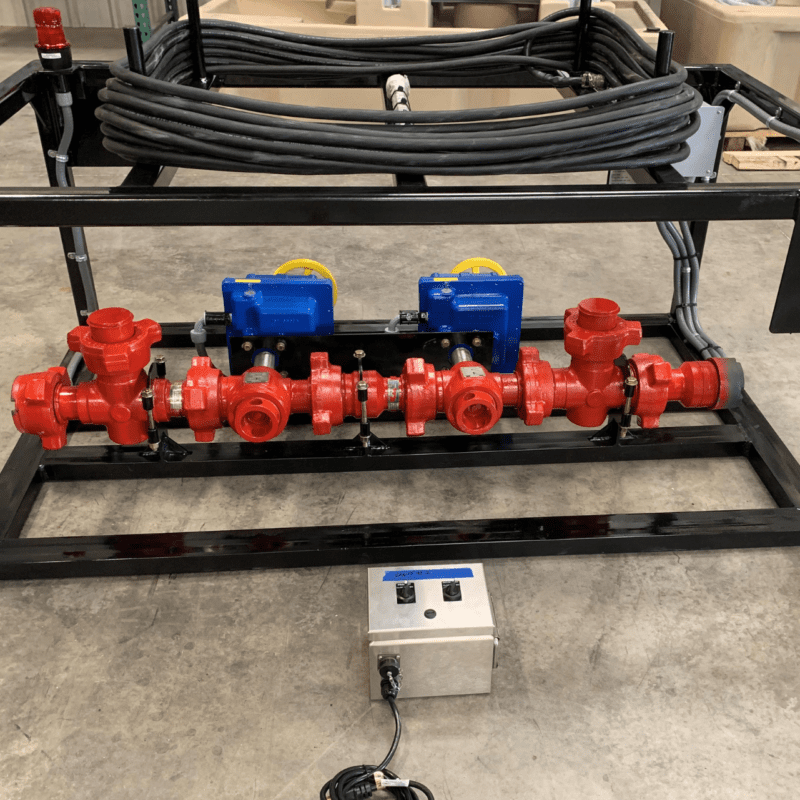

MGB’s Innovative Solutions deliver improvements in fuel efficiency, reducing wellsite emissions, and making frac sites safer for personnel led to MGB’s industry reputation for innovative leadership. MGB continues to deliver engineered solutions to wellsite challenges.

Our Goals

Innovation

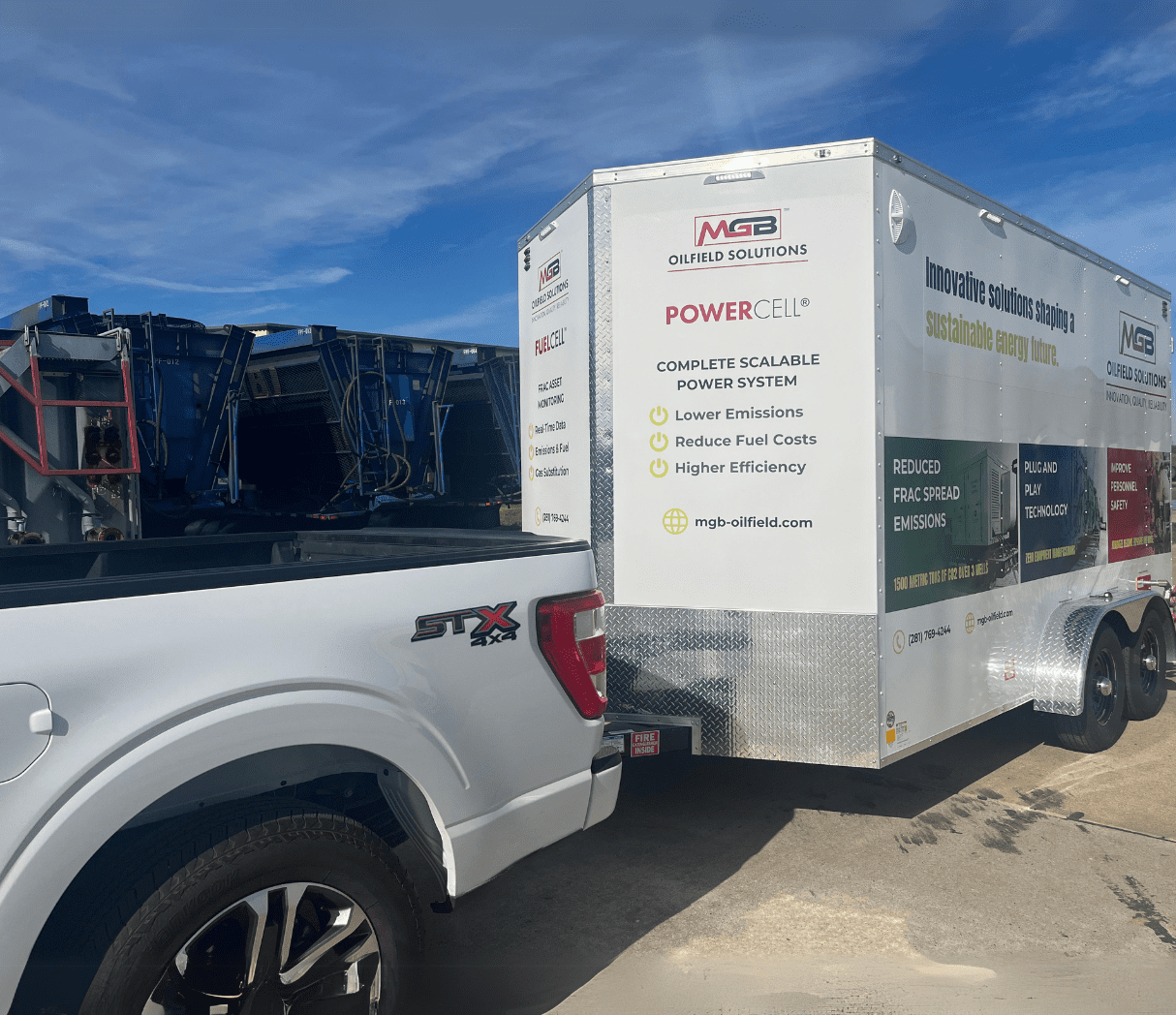

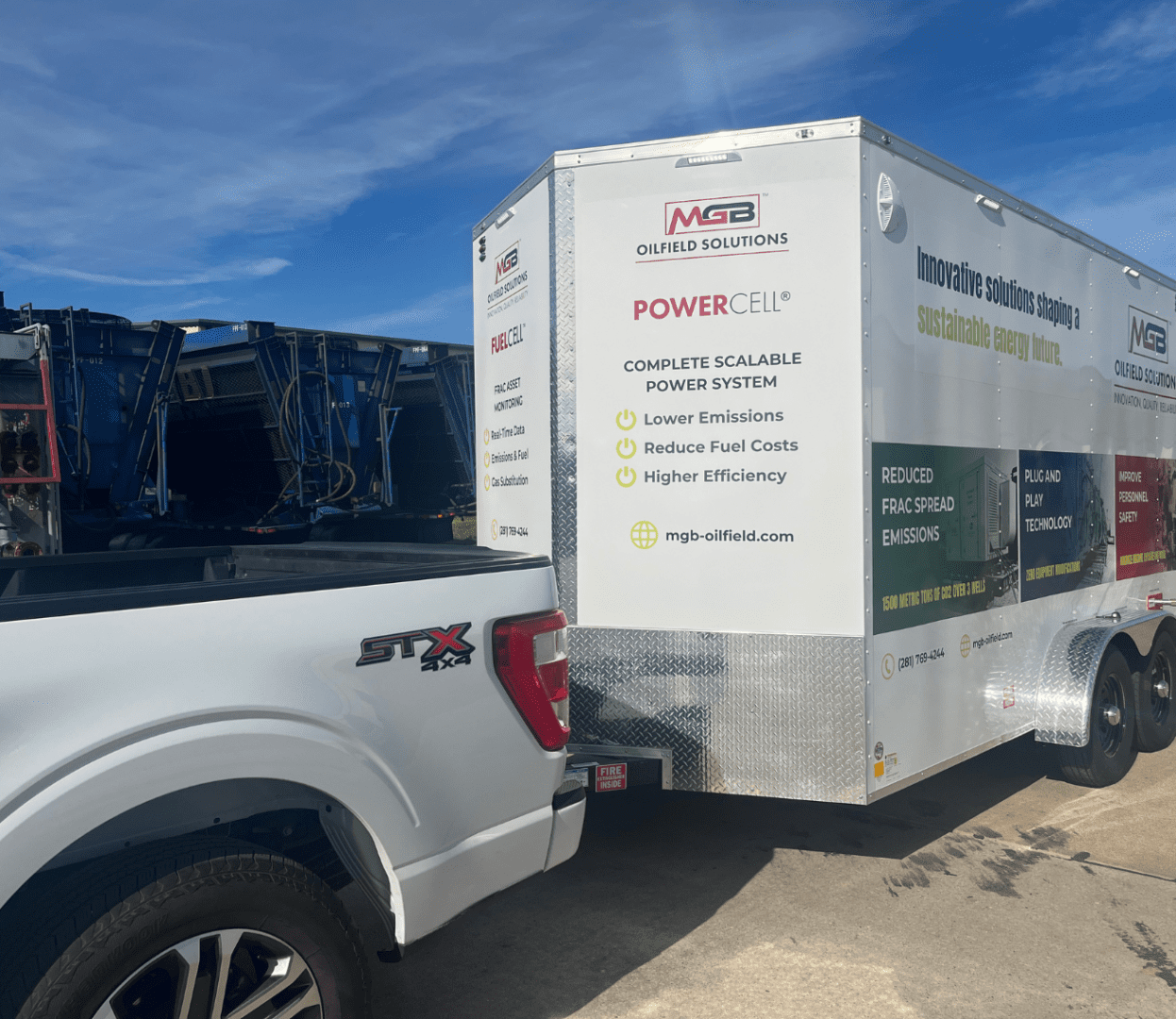

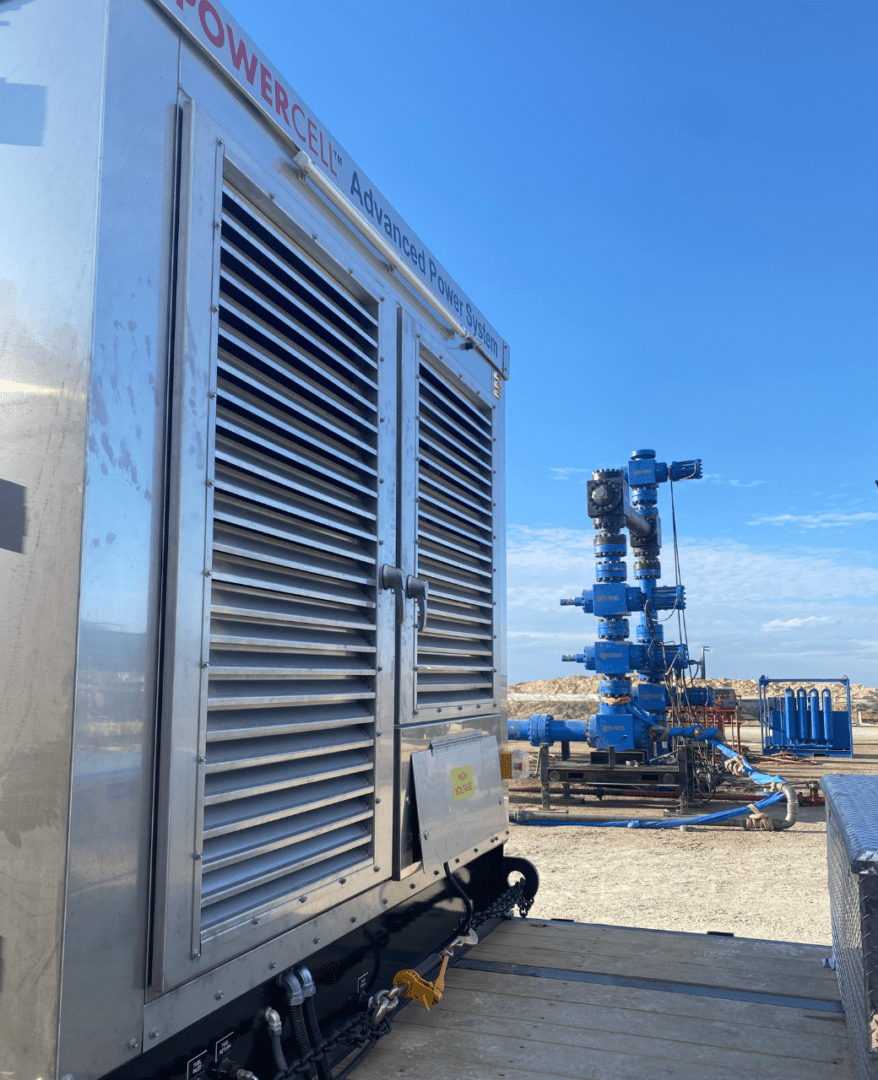

At MGB, innovation is the cornerstone of our design philosophy. Our PowerCELL technology platform is a lineup of innovative frac equipment designed to revolutionize efficiency and significantly diminish lifetime maintenance costs. Through relentless innovation, we set new benchmarks in the industry, ensuring our clients are equipped with technology that leads today and defines tomorrow.

Reliability

In the demanding environments of wellsites, equipment endurance is imperative. MGB’s system reliability includes internal self-monitoring software linked to our service centers 24 hours a day, 365 days a year, to ensure consistent performance. It’s our commitment to ensuring consistent, optimal performance, minimizing downtime, and maximizing productivity.

Quality

Every piece of equipment, be it newly designed or meticulously refurbished, is backed by MGB’s quality performance guarantee. This assurance is our promise of delivering unparalleled excellence, ensuring that every product not only meets but exceeds the rigorous demands of its operational environment.

Innovative Technologies for ESG Challenges

MGB provides innovative solutions to ESG challenges, including patented equipment technology, engineering, and refurbishment programs to improve our customers’ fiscal and HSSE performance.

Environmental. Minimizing our impact on the environment and creating a healthier future for all.

Social. Creating an inclusive and diverse working environment free of discrimination and harassment.

Governance. Doing business responsibly provides a positive return to our community and shareholders.

Products & Solutions

SPE HFTC 2023 Paper

Idling during hydraulic fracturing generates considerable emissions of NOX, CO, and particulate matter (PM). Field studies conducted during 2021-22 documented an average of 5 – 10 hours per day of diesel-powered idling during fracturing operations across multiple U.S. unconventional basins.